1-3KG Spring Balancer. Self-locking Tower-Type Lifting Hook Spring Holder Balancer. Steel Wire Rope Balancing Lifting Jack 1.5M

$28.68

Returns & Exchanges within 30 days

Returns & Exchanges within 30 days

30-day hassle-free returns

Money Back Guarantee

Money Back Guarantee

Full refund within 1-2 week of return receipt

3-Month Warranty

3-Month Warranty

Covers any possible defects in materials and workmanship

Free Shipping

Free Shipping

Enjoy free shipping on orders over $59.

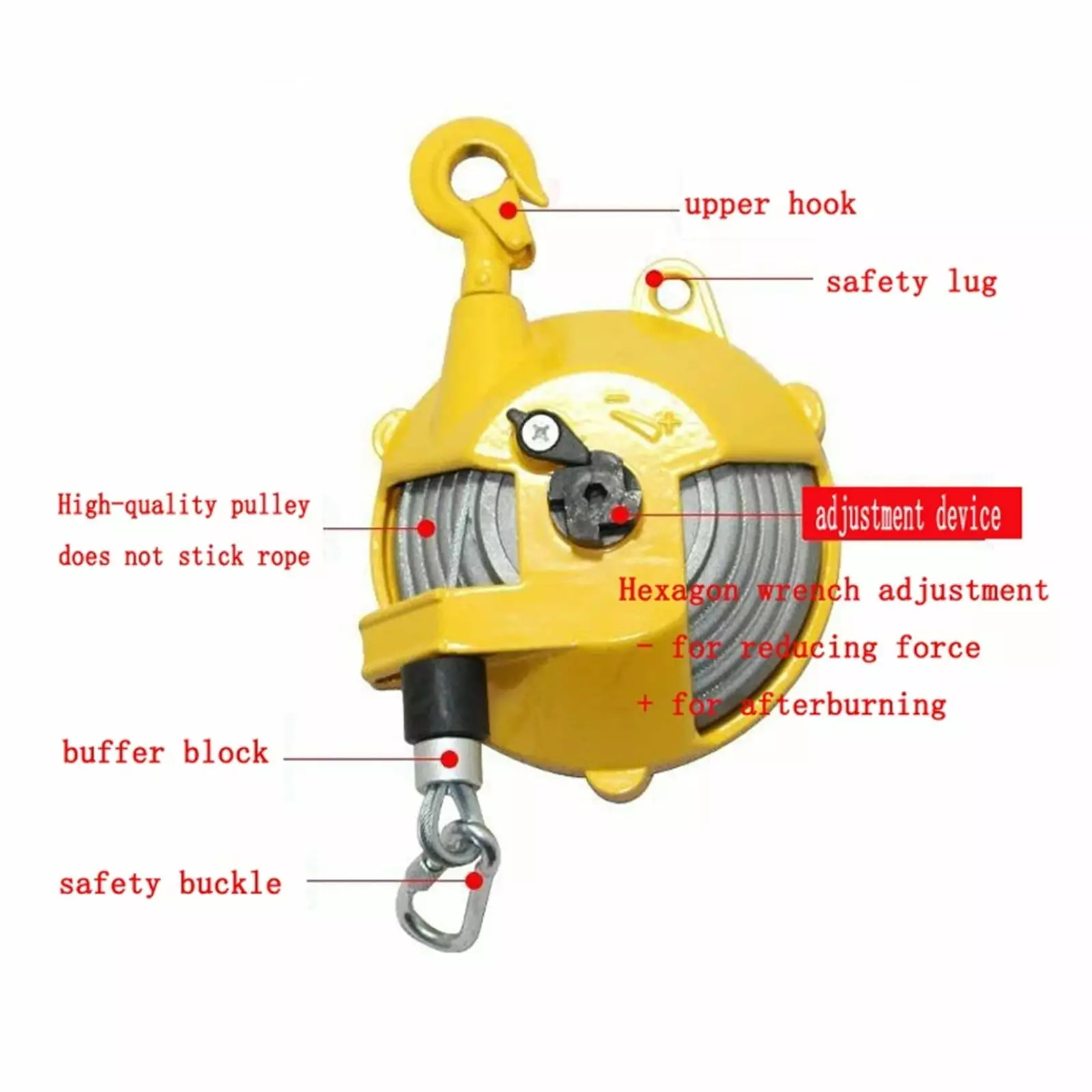

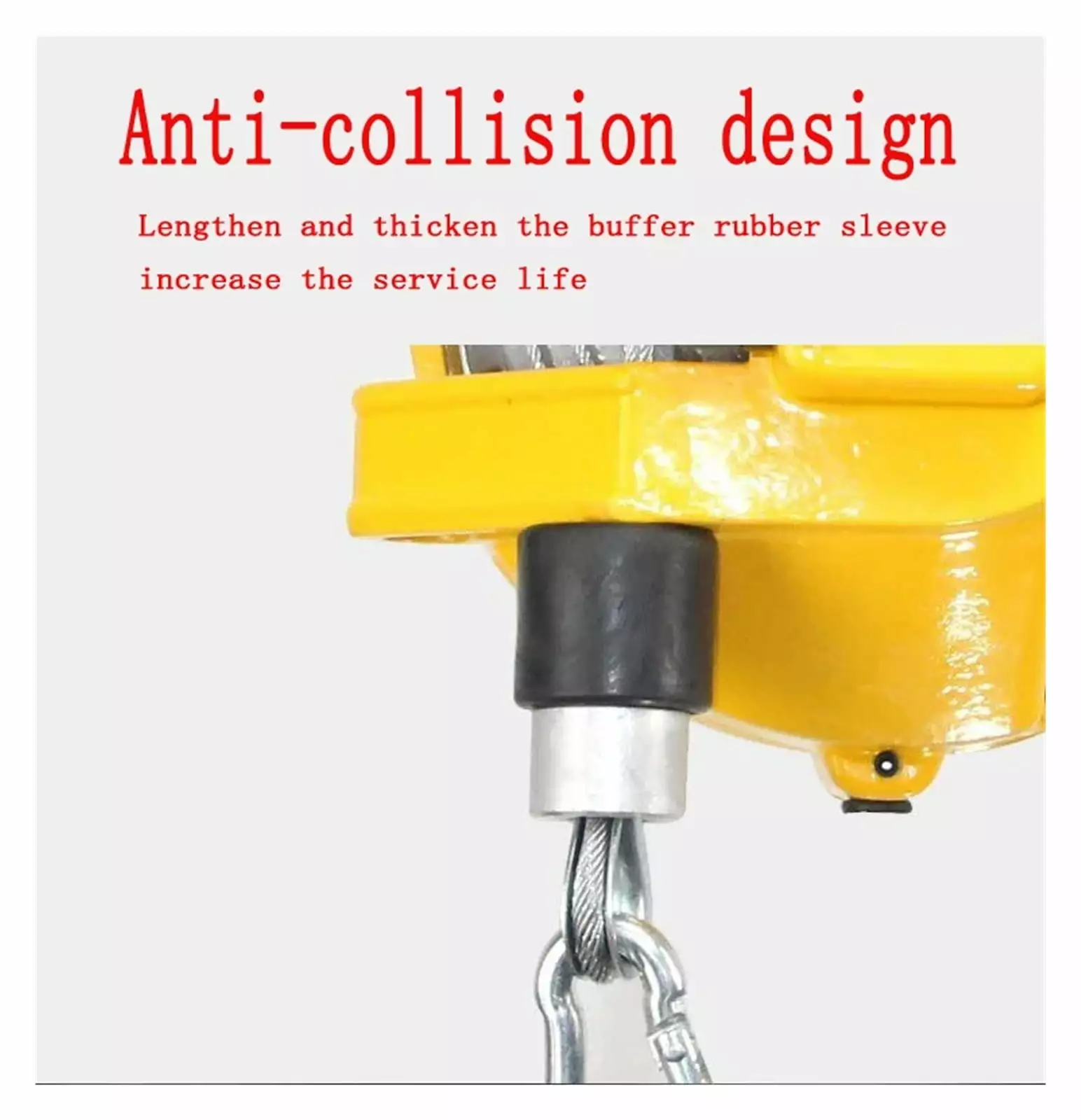

Paint cover: thickened alloy cover. paint process to reduce the weight of the fuselage. anti-wear

Tower wheel wire rope: aluminum alloy tower wheel. thick wire rope toughness. long fatigue life

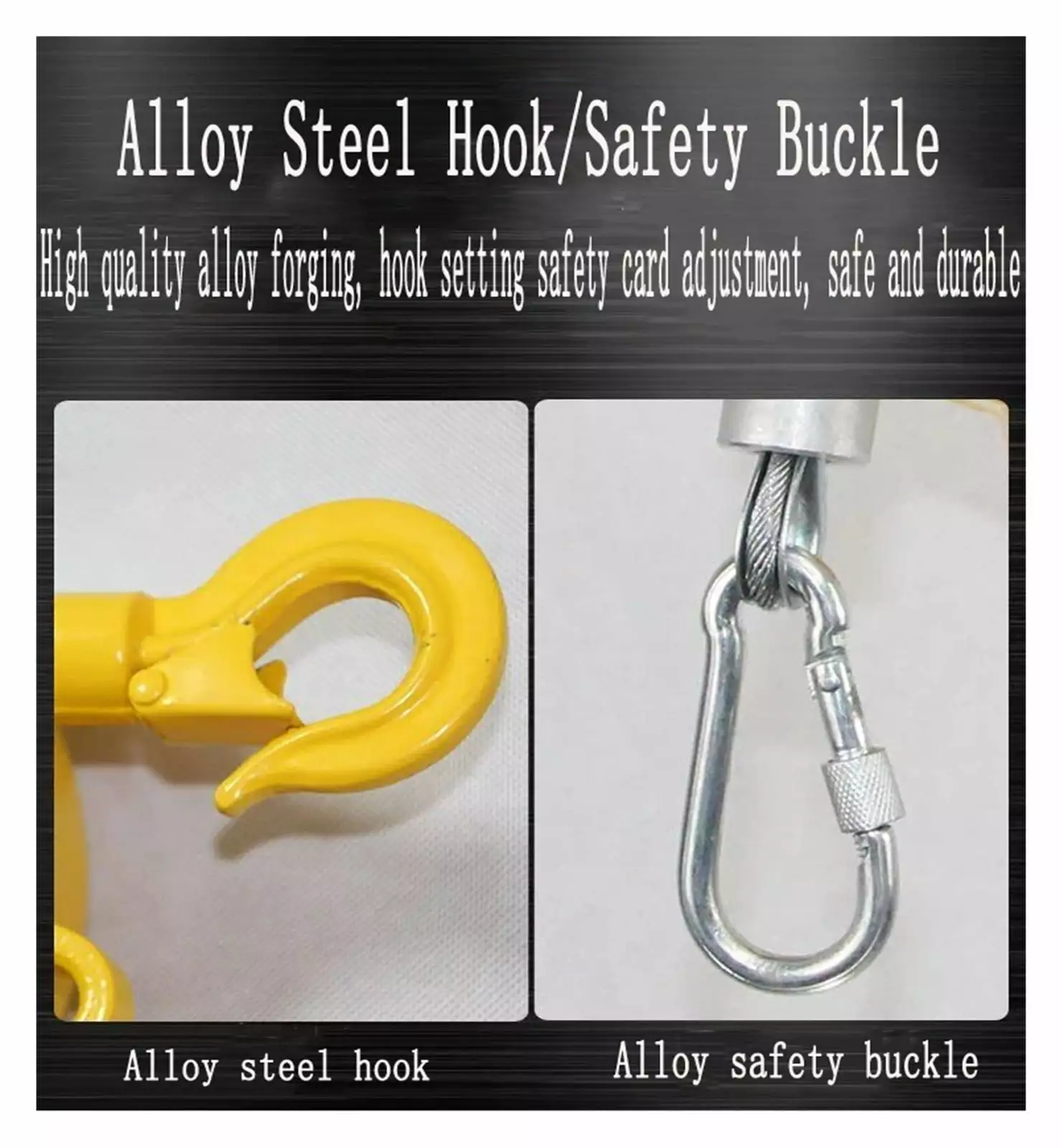

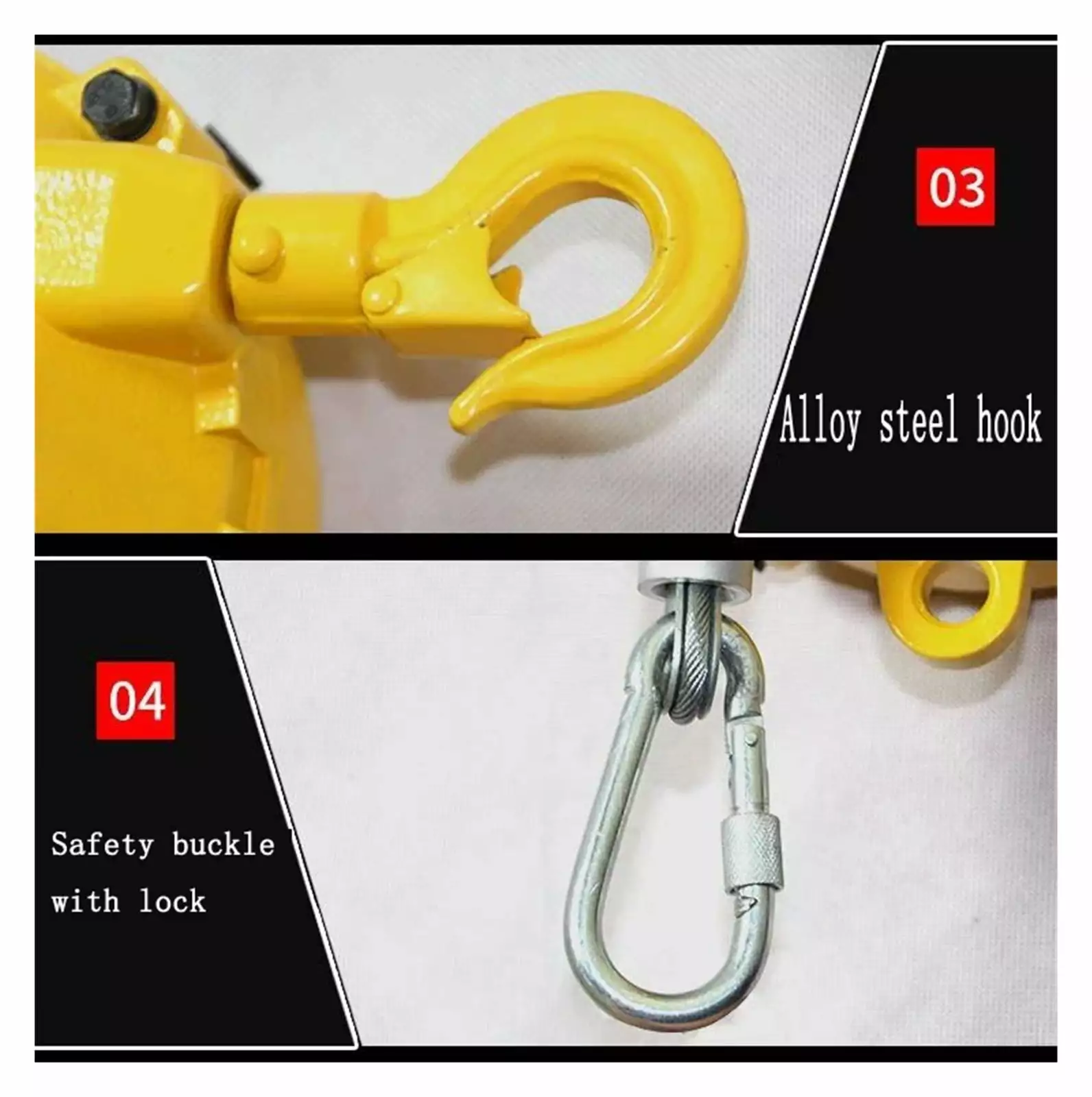

Alloy steel hook: alloy steel forging hook. with safety buckle. not easy to fall off

Safety buckle with lock: high strength safety buckle with lock. secure and secure

- How to use the spring balancer:

- 1. Rotate the balancer of the appropriate size according to the weight of the suspended object

- 2. Hang the lifting ring of the balancer on a solid beam or node above the station.

- And note: the user must put the safety hole on the beam or the node to ensure absolute safety in use. 3. Lift the operating tool to a position slightly higher than the height of the hook under the balancer and then hook it.

- 4. Adjust the balance weight of the balancer to be consistent with the weight of the tool used or slightly larger. so that the tool can be balanced at any position up and down. that is. the tool is in a weightless state

- 5. When the balancer is removed from the tool. it must be carried out after the steel ropes of the balancer are all involved in the tower wheel. in case the lower hook of the balancer cannot be pulled. causing a sudden unloading. and the hook is quickly retracted. causing injury or steel. Rope misalignment damages the balancer

- Do not pull or release the balancer without any reason when the balancer is not attached to the tool. so as not to cause the wire rope to be stuck in the wrong slot.

- The operating tool moves laterally. and the angle does not exceed 45??. The wire rope needs to be moved to the nearly vertical ground. retract.

- Precautions:

- . When disassembling the tower spring balancer. it is necessary to turn the adjusting worm anticlockwise first. so that the coil spring is completely in a relaxed state before other work can be performed.

- . The balancer should be checked for safety once a month. The main check contents are as follows:

- 1. Whether the fasteners are loose.

- 2. Check the upper and lower hooks for bumps. cracks and other defects.

- 3. Whether the safety rope is reliable.

- 4. Whether the shell and talon have cracks or serious wear.

- 5. Whether the shell device can work normally.

- . If it is not used for a long time. it should be unloaded and stored. and pay attention to moisture-proof to prevent the coil spring from rusting.

- balancer self-locking tower-type lifting hook. Lifting Sling. Material Handling Tools

Specifications

| Brand | Momo |

| Condition | New |

| Manufacturer | unknown |

Be the first to review “1-3KG Spring Balancer. Self-locking Tower-Type Lifting Hook Spring Holder Balancer. Steel Wire Rope Balancing Lifting Jack 1.5M” Cancel reply

Related products

Tool Equipment & Storage

Dragway Tools 3 Ton 6000 lb Heavy Duty Engine Hoist Cherry Picker Shop Crane

$160.00

Tool Equipment & Storage

Dragway Tools 2 Ton Load Leveler for Engine Hoist Shop Crane Cherry Picker Lift

$28.80

-

- Shop

- Home Improvement

- Auto & Tires

- Sports & Outdoors

- Car & Truck Racks

- Login

- SAVE 20% OVER $129 SAVE 30% OVER $159

Login

1-3KG Spring Balancer. Self-locking Tower-Type Lifting Hook Spring Holder Balancer. Steel Wire Rope Balancing Lifting Jack 1.5M

Reviews

There are no reviews yet.