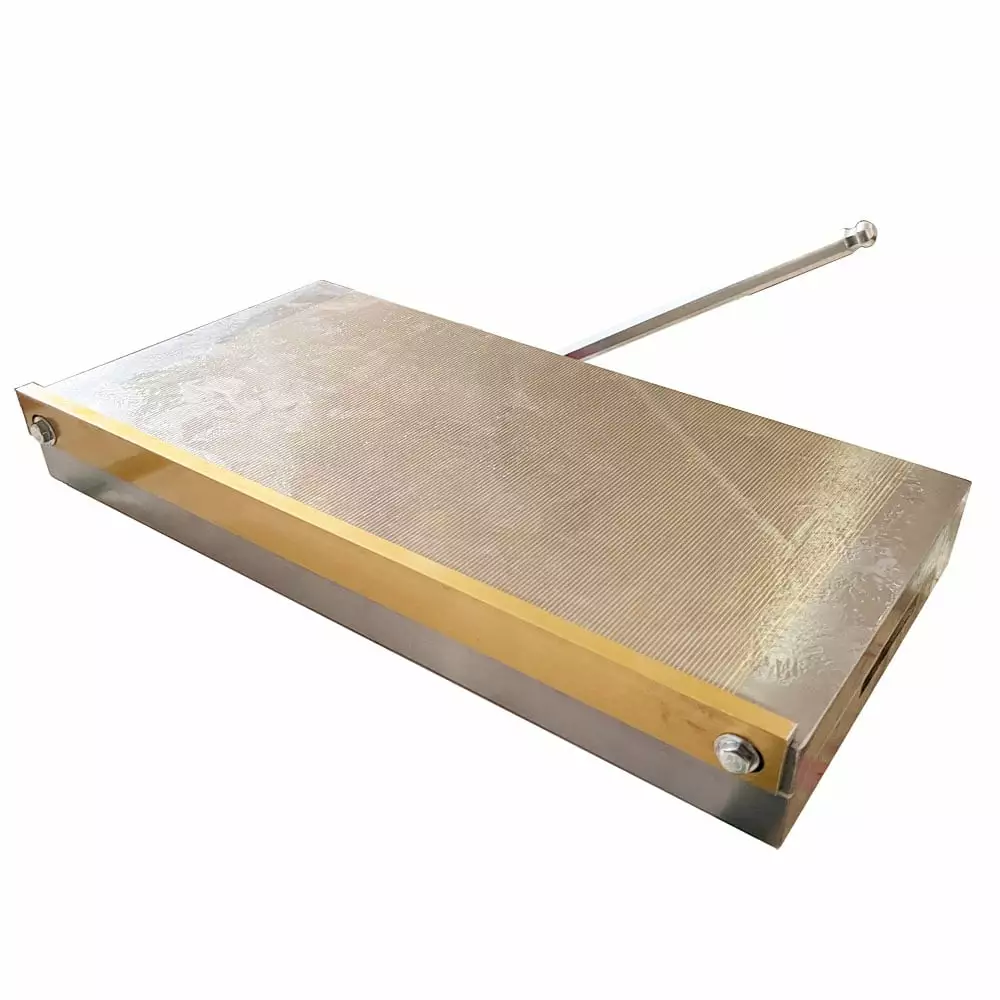

EQCOTWEA Magnetic Chuck Permanent Magnet Sucker 8*16 Rectangular Fine Pole for Grinding Machine Machining Workholding

$76.27

Returns & Exchanges within 30 days

Returns & Exchanges within 30 days

Money Back Guarantee

Money Back Guarantee

3-Month Warranty

3-Month Warranty

Free Shipping

Free Shipping

Product Overview:

Magnetic chuck is mainly used in a variety of surface grinding machine. tool grinding machine as a workpiece positioning processing. It has the features of high precision. uniform suction and safety. so that it is a processing positioning sucker sucker.

Parameters:

1. Suction: 100-120N/cm2

2. Size: 8*16inch

Method of use??

1. Put the workpiece on the suction table. and then insert the wrench into the shaft hole to turn clockwise180??. the workpiece can be sucked for processing.

2. The workpiece is completed. the wrench can be inserted into the shaft hole to turn counterclockwise 180??. you can remove the workpiece

Maintenance??

1. Sucker should be wiped clean before use to avoid scratching the surface. after using. the surface should be coated with oil to prevent corrosion.

2. Use of ambient temperature: -40 ??-50 ??.

3. Do not knock. to prevent magnetic reduction.

4. Strong dense pole permanent magnet sucker is for surface grinder. sparks machine. WEDM.

5. Very fine spacing. uniform magnetic distribution. particularly for processing small thin parts.

6. Worktable precision no change while magnetizing and demagnetizing.

7. Panel with special treatment. no leakage. to prevent corrosion of cutting fluid. To prolong service life of the disk. it can be placed on the cutting fluid for storage. Six-surface fine grinding processing. the sucker can be used in vertical direction on the wire cutting machine cutting.

8. High-performance magnetic steel disk. with suction. almost no remanence.

Notice: Gold and silver are shipped randomly.

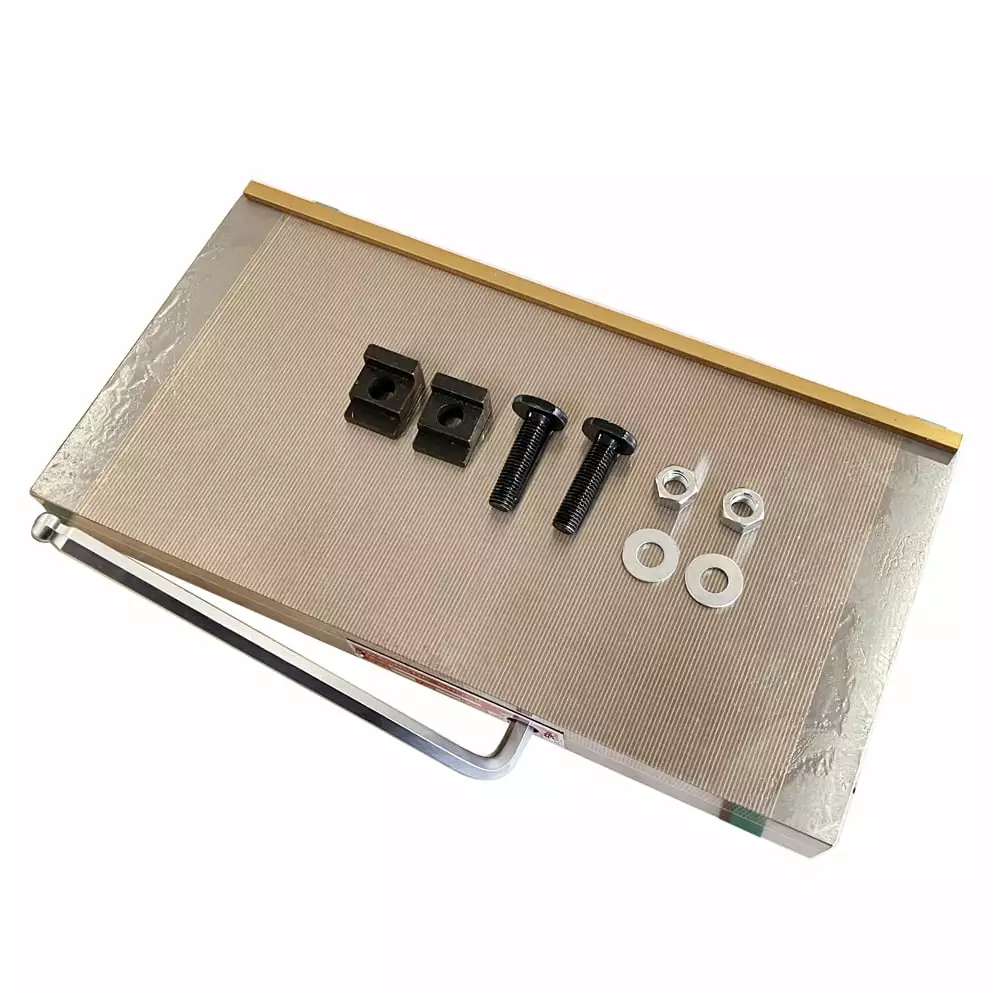

Item Included: 170427

EQCOTWEA Magnetic Chuck Permanent Magnet Sucker 8*16 Rectangular Fine Pole for Grinding Machine Machining Workholding

-

Fine pole permanent magnetic chuck is mainly used in surface grinding machine. tool grinding machine as a workpiece positioning processing. With feature of high precision. uniform suction and safety. so it is a processing positioning sucker.

-

Six sided precision grinding processing. the suction cup can cut the wire cutting machine in the vertical direction. The magnetic force is evenly distributed. High performance magnetic steel disk with suction and almost no residual magnetism.

-

Panel with special treatment. no leakage. to prevent corrosion of cutting fluid.

-

It with uniform suction force. fine magnetic pole gap. uniform magnetic force distribution. and the effect is particularly good when processing thin and small workpieces obvious.

-

The handle on the magnet has a locking open/locking close mechanism. which requires manual operation between two states.

Specifications

| Brand | EQCOTWEA |

| Manufacturer Part Number | 170427 |

Be the first to review “EQCOTWEA Magnetic Chuck Permanent Magnet Sucker 8*16 Rectangular Fine Pole for Grinding Machine Machining Workholding” Cancel reply

Related products

Tool Equipment & Storage

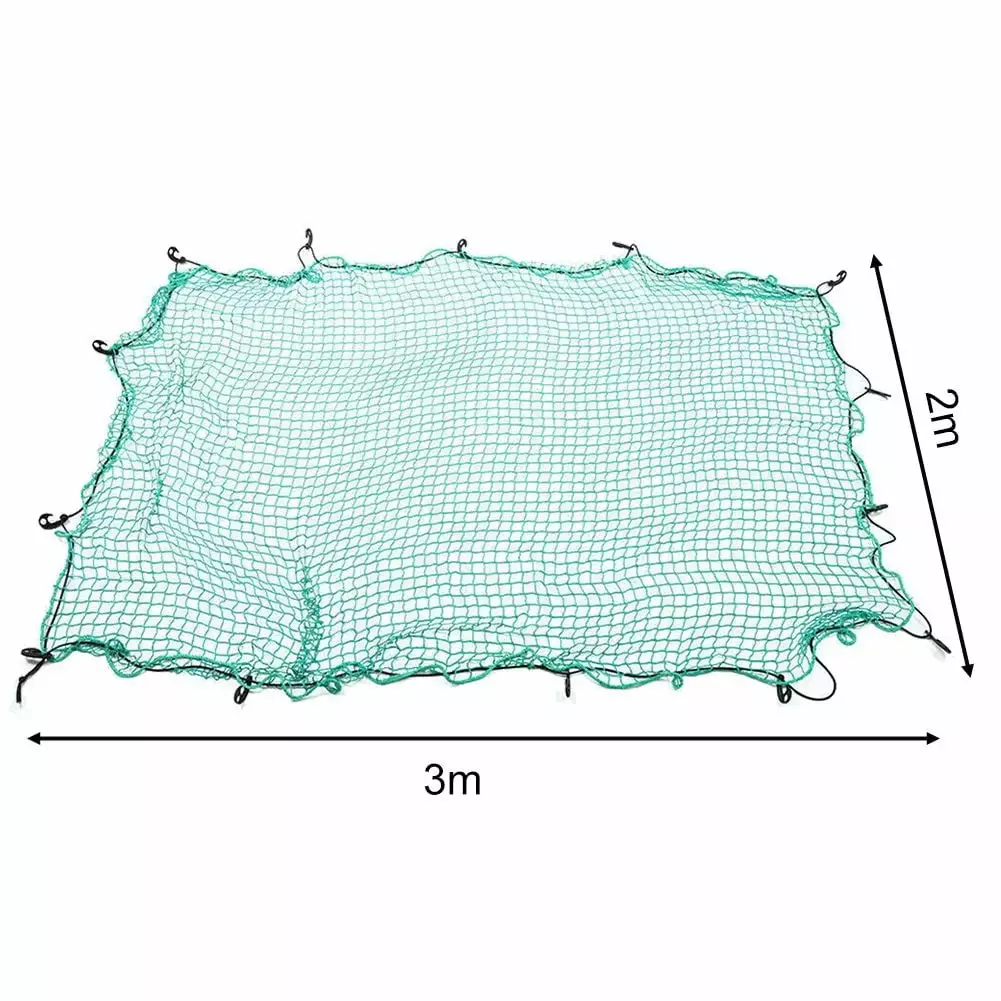

CURT 83036 1-1/2-Inch x 14-Foot Yellow Nylon Ratchet Strap. 5.000 lbs. Break Strength

Tool Equipment & Storage

LUMICHY 4Pcs Wear-proof Ladder Feet Cover Ladder Butt Protectors Ladder Foot Pads

-

- Shop

- Home Improvement

- Auto & Tires

- Sports & Outdoors

- Car & Truck Racks

- Login

- SAVE 20% OVER $129 SAVE 30% OVER $159

Login

Reviews

There are no reviews yet.